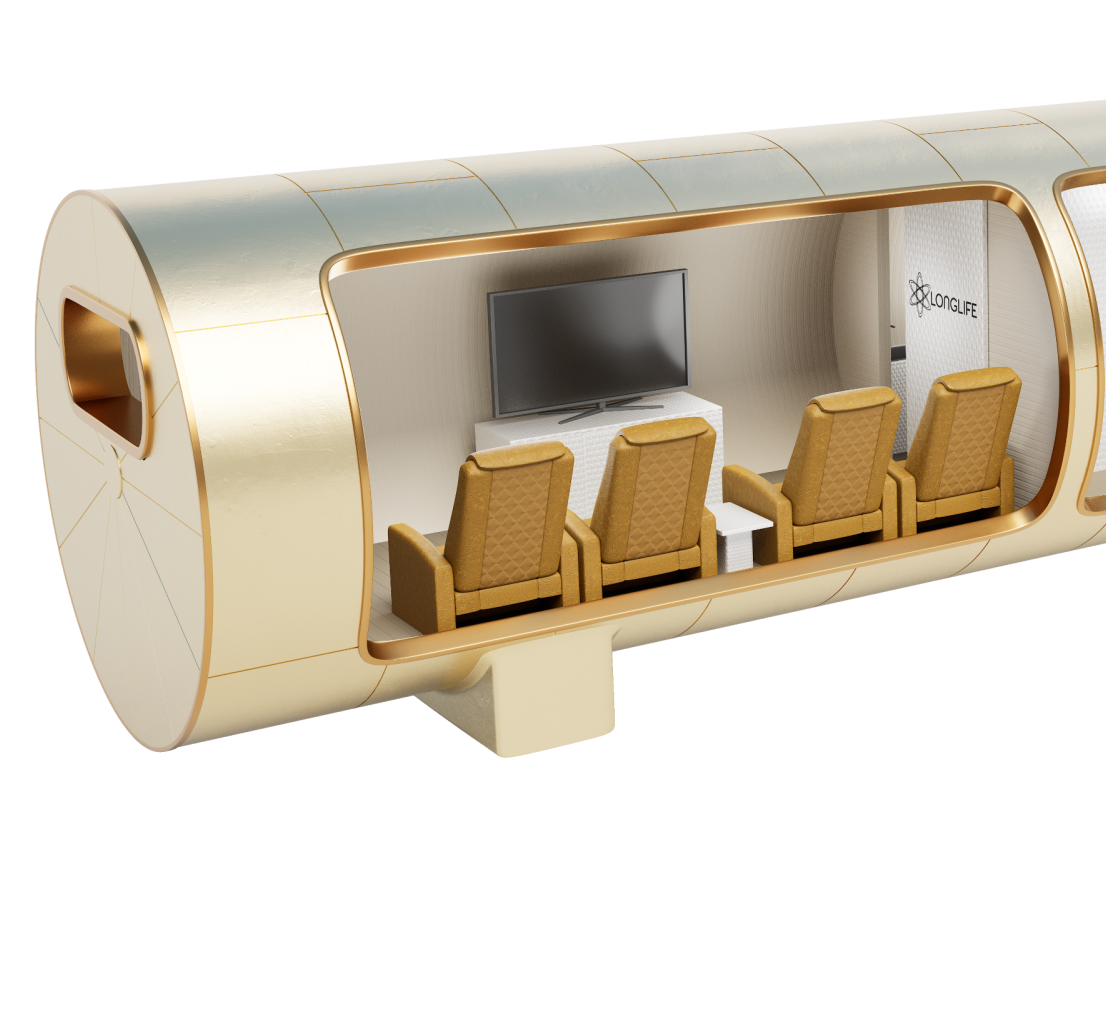

Long Life also offers installation of the Normotech™ system in existing pressure vessels — both new and used. This allows clients to benefit from advanced atmospheric stabilization technology.

Our offer also includes comprehensive services for repair, modernization, and adaptation of normobaric chambers to meet the latest technical and safety standards. This covers fault diagnostics, replacement or upgrading of control systems, installation of modern components, as well as full service support and consulting to optimize chamber performance.

If you’re looking for:

a modern control system for your normobaric chamber,

automation solutions for normobaric systems,

system installation in an existing pressure vessel,

O₂, H₂, and CO₂ gas sensors with calibration and parameter visualization

Contact us. We’re ready to collaborate with installers, manufacturers, and end users.